The risky thing about being a quantum registering geek or enthusiast, for those of us less inclined to humility is that, unavoidably, a conspicuous inquiry comes up. Furthermore, that question is: “Yet how would a quantum PC be able to respond that a traditional PC can’t?”

It’s somewhat of a buzzkill question, truth be told. Not on the grounds that quantum registering can do nothing genuine world-cool, but since our restricted personalities haven’t exactly figured out how to foster calculations that would be awfully valuable for the benefits quantum impacts could possibly proffer. Assuming this were a profound predicament, for example, it would be similar to a human attempting to make sense of the idea of an all-knowing, all-powerful divinity. It’s hard on the grounds that we don’t have the foggiest idea what we don’t have the foggiest idea.

In the tiny domain of what we have as of now distinguished as relevant to quantum processing, quantum PCs can work with a rundown of known calculations at Quantum Algorithm Zoo. Yet, that rundown, similar to one more on Wikipedia, is a work underway. One must be happy with digging into the domain of cutting edge numerical frameworks Oracles, as they’re called-which, incidentally, is somewhat of a restricting variable.

The current – and rather unforgiving truth is that there aren’t exactly any genuine issues just feasible with a quantum PC. Basically not at this moment. Anything we presently care about can undoubtedly be settled on a traditional PC in the event that you give it a couple million or billion years (and a lot of force). Few out of every odd computational nail needs a quantum-figuring hammer. Katie Pizzolato, IBM QStart chief, and William Hurley, organizer and CEO of Strangeworks, a quantum processing startup in Austin, Texas, expressed their impressions on the present status of quantum registering.

No Denying Quantum Computing’s Potential

We’re as yet in the beginning phases of quantum registering, and essentially a couple of years from having the option to take care of issues old style PCs can’t, Pizzolato said, adding, however, that this didn’t mean individuals weren’t at that point attempting. “We have in excess of 130 associations addressing Fortune 500 organizations, scholastic foundations, research labs, government labs, and new companies all over the planet trying different things with genuine business issues today on genuine quantum equipment,” she said.

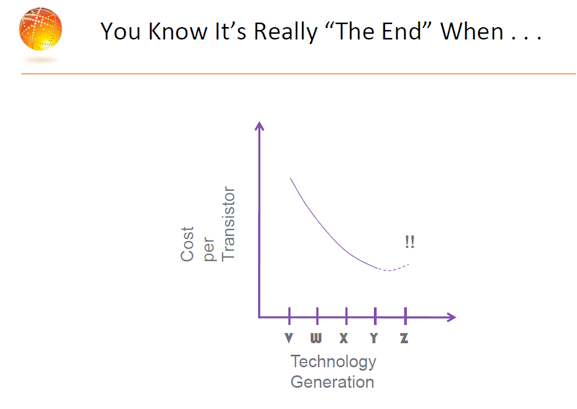

The explanation quantum registering keeps on catching our creative mind and produce such a lot of interest is that its expected speed for tackling a specific arrangement of issues is still enormously captivating, regardless of whether we aren’t exactly there yet. In principle, a quantum PC’s degree of intricacy implies it could tackle epic difficulties across a plenty of ventures, from drugs to move to framework to fund and online protection. This is on the grounds that quantum PCs are proficient at considering madly huge numbers and are great at tackling numerical riddles, for example, the Traveling Salesman issue, which would rapidly overpower an old style PC.

“I think the public will probably miss all the miracle of quantum figuring,” Hurley said. “They’ll be impacted by it, yet no doubt not immediate clients and in this manner will presumably not be shocked.” Hurley said a “executioner application”- type calculation for individuals to highlight while examining quantum figuring capacities isn’t probably going to be grown soon.

Things being what they are, the reason even irritation being energetic about it in the event that it’s so difficult to try and concoct true issues to settle? Since a quantum PC can’t tackle a major genuine issue doesn’t mean it can’t help simultaneously, Hurley said. Without a doubt, he accepts that a portion of the computational intricacies found in environmental change and malignant growth examination would be great possibility for investigation from a quantum processing point of view.

“While I don’t know quantum will ‘address’ both of them, I in all actuality do figure it will colossally affect the cutting edge in the two fields,” he said.

Pizzolato is hopeful about quantum processing’s effect on numerous areas of science and innovation. “The thoughts behind it are generally creative, and new ones are as a rule continually investigated,” she said. Quantum analysts were ceaselessly “pushing the limits of how can be managed a quantum PC, and simultaneously sorting out what it can mean for the world we live in,” she said. Doing this, nonetheless, requires steady commitment with innovation pioneers in ventures like the monetary administrations area, energy, hardware, auto, science, medical care, and carriers.

Throughout the following ten years, Pizzolato has high expectations for things like the recreation of new materials or medication revelation.

There are a few issues for which quantum PCs enjoy a characteristic remarkable upper hand over conventional PCs, for example, the ones that are in a general sense quantum in nature, similar to quantum science,” Pizzolato said. AI was one more great possibility for quantum processing speed increase, she said. “We anticipate that more exploration should lay out an edge on useful applications,” she said.

Since the overall population can’t see unmistakable outcomes from quantum registering yet, doesn’t mean it doesn’t make any difference for genuine issues, Hurley said. “I think we see this in the billions of dollars state run administrations are putting resources into quantum figuring,” he said. “It’s a lot greater arrangement than individuals might naturally suspect from the outset.

The U.S. as of late reported a $1 billion (USD) quantum and man-made reasoning drive, which incorporates $300 million toward growing new Department of Energy labs zeroed in on quantum figuring.

End

Maybe similar as Douglas Adams’ supercomputer ‘Profound Thought’ in “The Hitchhiker’s Guide to the Galaxy” whose solution to “the Ultimate Question of Life, the Universe and Everything” is 42-it’s actually not necessary to focus on tackling for the inquiries we know how to pose, yet posing the right inquiries that quantum registering can settle.

Since, do you have any idea what a quantum PC mightn’t? It can let you know whether it can do nothing helpful. What’s more, it very well may be for the imaginative among us to make sense of that.