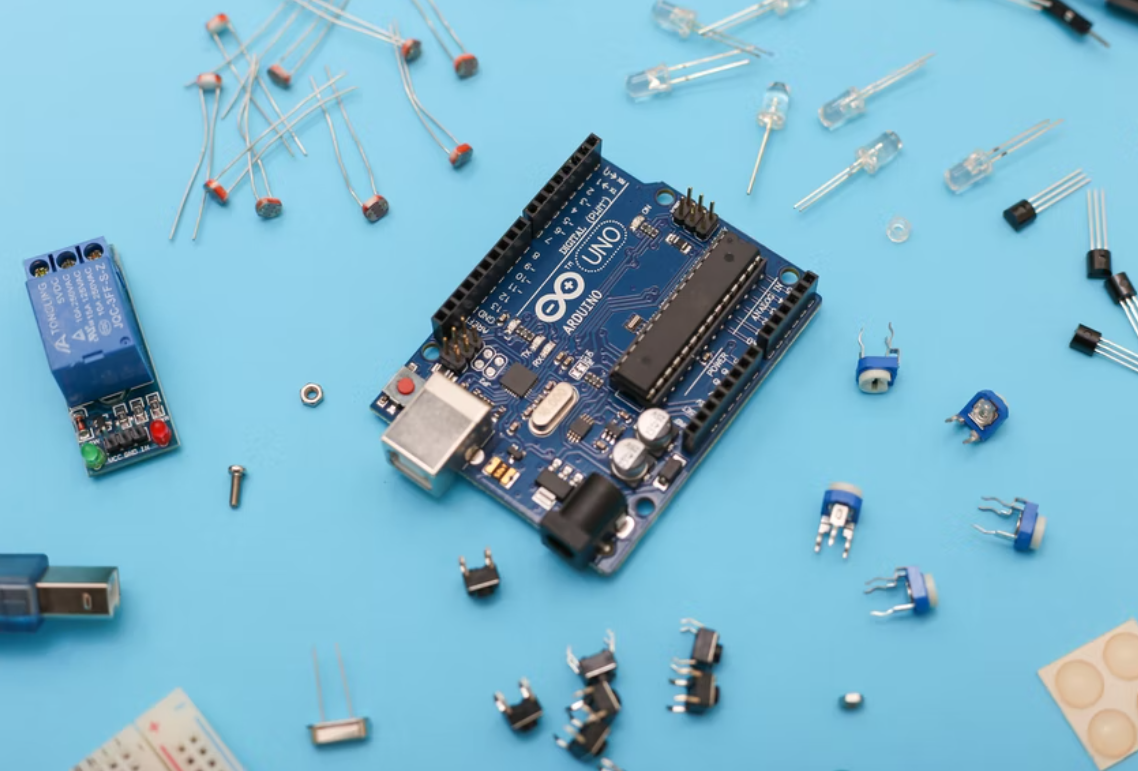

In 2017, The MagPi Magazine – the authority Raspberry Pi magazine – reported that over 12.5 million of the Raspberry Pi single-board PCs (SBCs) had been sold since the 2012 presentation of the primary form. The Pi has not just shown to be a #1 of specialists, producers and designers the same, it has even gotten the interest of AI scientists at Microsoft.

Combined with its blast in fame is the rundown of frill that supplement this SBC. Coming up next is a rundown of suggested extras for you, the Raspberry Pi fan.

If, notwithstanding, you’re not there yet, we can assist you with the beginning. So we should begin with a pack.

The starter pack for the new Raspberry Pi proprietor

We suggest Raspberry Pi Foundation’s own starter pack for an overall investigation of the SBC. The unit incorporates a Raspberry Pi 3 Model B, 8-GB or 16-GB NOOBS SD card, case, a 2.5-A multi-locale power supply, 1-m HDMI link, optical mouse, and a console with top-notch scissor-switch activity.

What we truly like about this pack is that it accompanies a duplicate of “Undertakings in Raspberry Pi.” The writer, Carrie Anne Philbin, guides you through your new SBC obtaining, exhibits how to compose programs in Scratch and Python, utilizes engineer devices like Minecraft Pi and Sonic Pi and examines a few first ventures.

Equipped with a Raspberry Pi, now is the ideal time to take a gander at ways you can get the majority of your SBC – through embellishments and direction.

Raspberry Pi Cookbook

First up is the book by Simon Monk that goes past the manual in the starter pack to give you north of 200 recipes or tasks. It will show you how to set up and deal with the board, associate it to an organization, work with its Linux OS, program in Python, control other equipment including engines, secure data from sensors and much more. The Raspberry Pi Cookbook is simply $39.99.

To dive further into the Python programming language, we additionally suggest Python for Microcontrollers: Getting Started with MicroPython. This book won’t just show you the Pi’s Python local language yet arm you with eight extra model tasks.

Google AIY Voice Kit for Raspberry Pi

To rapidly construct an all set venture – in about 90 minutes level – attempt AIY Projects’ Google AIY Voice Kit. For just $29.99, you can construct yourself your own voice-actuated home right hand.

The pack incorporates a voice Hardware-Attached-on-Top (HAT) embellishment board, voice HAT mouthpiece board, 3-in. speaker, arcade-style pushbutton, edge and plastic stalemates. You’ll should simply supply a Raspberry Pi 3 board, a SD card, size “00” Phillips screwdriver and some Scotch tape.

Happiness Bonnet

In the event that you are wanting to construct a gaming framework, you’ll require a game regulator. Adafruit’s Joy Bonnet sits on top of a Pi Zero to empower arcade-like control. For just $15.61, this deal regulator is a completely collected HAT, and that implies you don’t have to bind anything. All you want to do is to introduce your content on the Pi and transfer your emulator, like the RetroPie or the EmulationStation.

You can likewise utilize the Joy Bonnet with Pi A+ or B+/2/3, however it’s the Pi Zero that it fits the best.

Raspberry Pi Sense HAT

Prepared to utilize sensors to assemble games, control other equipment or lead science tests? The Raspberry Pi Sense HAT appends a few on-board sensors on top of the Raspberry Pi by means of the GPIO pins. It was made for the Astro Pi mission and was sent off to the International Space Station in December 2015 to perform science tests.

This HAT incorporates a gyro, accelerometer, magnetometer, temperature sensor, barometric tension sensor and a mugginess sensor. A 8 × 8 RGB LED grid will show information from the sensors, and you can utilize a five-button joystick to connect with your task here on Earth.

You can purchase the Sense HAT for $70.39 and download Raspberry Pi Foundation’s Python library here to control it.

Adafruit 7-in. LCD TFT touchscreen

Transform the Pi into a tablet with Adafruit’s 7-in. touchscreen, which gives you a 1,024 x 600 goal that is a decent counterpart for inserted processing needs.

You can drive it over USB and contribution over HDMI. Included is a resistive touchscreen-to-mouse regulator (AR1100) – a board that handles A/D change – as well as adjustment programming. A wired PCB with buttons permits you to enter the showcase’s menu for changing splendor, differentiation and variety.

On the off chance that you are fostering a LED divider show, consider adding an Adafruit RGB Matrix HAT to make a looking over show utilizing 16 x 32, 32 x 32, and 32 x 64 RGB LED frameworks with HUB75 associations.

The Pi-Top Laptop

For the people who are considering utilizing the Pi a dainty client or more, the Pi-Top will get you an open-source PC for just $299.99. You’ll get a 14-in. 1080p LCD, complete with a nook that incorporates a console, trackpad and battery, a PCB to deal with the associations between the Pi and the remainder of the framework, 8-GB SD card, links and charger.

What’s best about this Pi-to-Laptop converter is that gathering is pretty much as simple as “clicking” the provided parts into place.

Pimoroni SkyWriter HAT

Our last pick is an extra that will acquaint you with the developing signal control market. With the SkyWriter HAT, you can carry the ability to utilize signals to your Raspberry Pi (Models 3, 2, A+, B+ and Zero) for just $18.99.

The HAT has an electrical close field 3D/motion sensor that can recognize your developments to the extent that 5 cm away and can work from behind a non-conductive material-like texture. It tracks finger developments and signals like tap/twofold tap and finger flicks.

To get more familiar with these frills and investigate extra choices, go to Arrow.com. On the off chance that you pick to make a buy and spend more than $20, you’ll appreciate free one-day transport.